Son Yazılar

Achieving Energy Savings with Thermal Screens

Quality Standards in Greenhouse Materials

A Guide to High-Quality Production with Hydroponic Flower Greenhouses

Risk Management and Insurance in Commercial Greenhouses: Secure Your Investment

Permits and Documents Required to Set Up a Greenhouse: Step-by-Step Guide

Most Suitable Regions for Greenhouse Investment in Turkey

Key Considerations When Planning a Greenhouse Project

What is the Greenpad (Evaporative Cooling) System?

Greenhouse Electrical System: Safe Energy Management

How to Install Greenhouse Automation? A Step-by-Step Guide

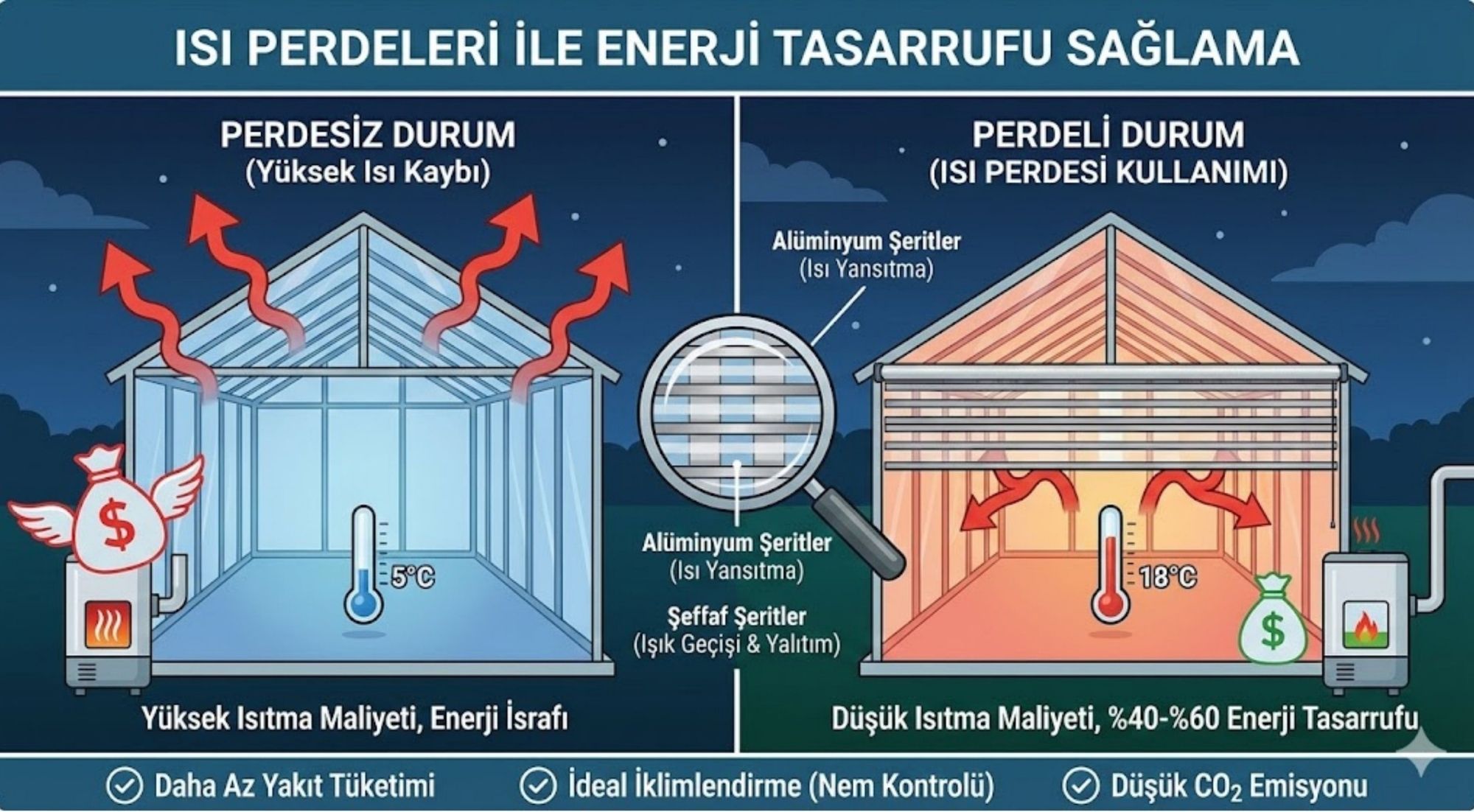

Achieving Energy Savings with Thermal Screens

The most effective way to halt this energy leakage and dramatically reduce heating bills is to utilize high-tech Thermal Screens (Curtains).

One of the most critical factors determining profitability in modern greenhouse farming is the ability to keep operating expenses under control. Particularly in cold climate regions or during winter production, heating costs constitute a significant portion of total expenses. Unfortunately, a large portion of the energy spent to keep the internal temperature at ideal levels for plant development escapes into the atmosphere through the roof and side surfaces due to a lack of insulation.

Heat Loss: The Hidden Enemy of Greenhouse Farming

When no insulation layer (screen) is used in a greenhouse, the hot air produced by heating systems rises due to the laws of physics. This heat, reaching the roof surface, rapidly escapes through the glass or plastic cover. This situation causes heating boilers to run continuously and at high capacity to reach the desired temperature. The result is low internal temperatures despite tons of fuel consumption and a serious financial loss for the business. This scenario is literally throwing energy and money into the air.

Working Principle of Thermal Screens: A Heat Shield

Thermal screens are not simple shading nets; they are movable insulation barriers that can be opened and closed between the greenhouse roof and the plants. The secret to the high performance of these screens lies in their specially engineered textures.

They usually consist of a combination of aluminum strips and transparent carriers:

The Role of Aluminum Strips:

Shiny aluminum surfaces reflect the internal heat (infrared radiation) back like a mirror, ensuring the heat remains at the level where the plants are located.

Insulation Layer:

When the screen is closed, it creates a layer of stagnant air between the roof and the screen. This buffer zone provides excellent insulation by slowing down the transfer between the cold air outside and the warm air inside.

40%-60% Energy Savings and Ideal Conditions

In a greenhouse using a thermal screen, heat loss is minimized when the screen is closed during the night or on cold days. The heating system runs much less frequently and easily reaches the target temperature (e.g., ideal levels like 18°C).

Research and field applications show that a correctly selected and applied thermal screen system provides savings of 40% to 60% in the greenhouse's heating energy requirements. This effectively means cutting heating costs in half.

Extra Benefits: Humidity Control and Environment

In addition to energy savings, thermal screens contribute significantly to greenhouse acclimatization:

Humidity Management:

The screen, closed at night, prevents moisture generated by plant transpiration from reaching the cold roof surface and condensing (dripping). This significantly reduces the risk of fungal diseases.

Environmental Impact:

Less fuel consumption means lower CO2 emissions. This ensures a more sustainable and eco-friendly production model.

In summary; thermal screens are indispensable equipment for a modern and competitive greenhouse business, amortizing the initial investment cost in a short time with the massive energy savings they provide.