Son Yazılar

Achieving Energy Savings with Thermal Screens

Quality Standards in Greenhouse Materials

A Guide to High-Quality Production with Hydroponic Flower Greenhouses

Risk Management and Insurance in Commercial Greenhouses: Secure Your Investment

Permits and Documents Required to Set Up a Greenhouse: Step-by-Step Guide

Most Suitable Regions for Greenhouse Investment in Turkey

Key Considerations When Planning a Greenhouse Project

What is the Greenpad (Evaporative Cooling) System?

Greenhouse Electrical System: Safe Energy Management

How to Install Greenhouse Automation? A Step-by-Step Guide

Greenhouse Electrical System: Safe Energy Management

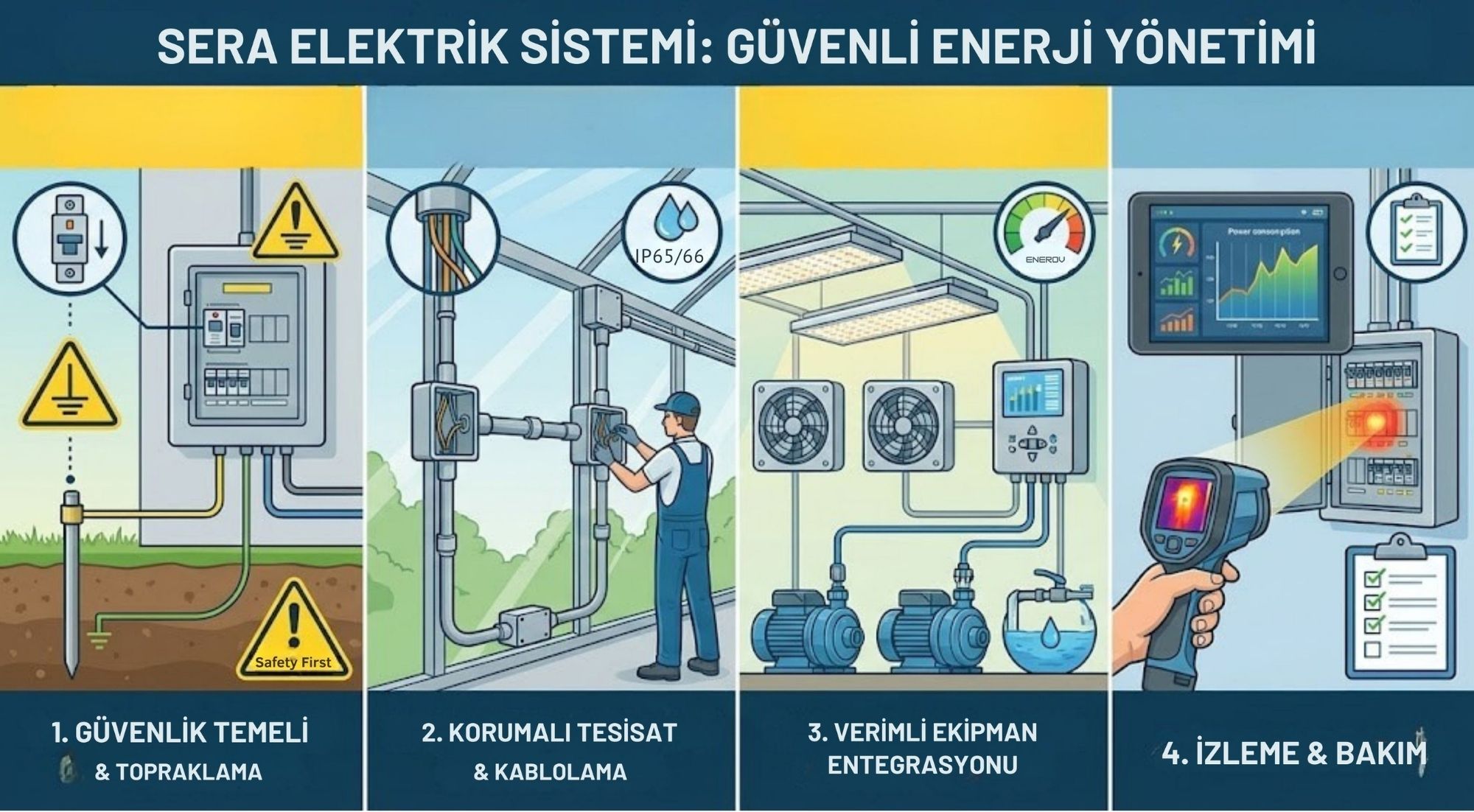

The greenhouse electrical system is one of the most critical components of modern greenhouse farming. Lighting, heating, irrigation, ventilation, automation, and sensor systems all require a safe electrical infrastructure. An incorrectly planned electrical installation can lead to both equipment failures and production losses. Therefore, safe energy management in greenhouses is a subject as vital as efficiency. Below, you can find the basic steps for the correct installation of a greenhouse electrical system.

Safety Foundation & Grounding

The most important element of the greenhouse electrical system is the correct grounding infrastructure. Since humid environments increase electrical risk, professional grounding is mandatory in greenhouses. Grounding protects both employees and equipment against electrical leakage.

Points to consider in grounding:

All panels and sockets must be secured with residual current protection relays.

Heating systems, pumps, fans, and motors must be protected with separate safety lines.

Grounding rods must be positioned at the appropriate depth and measured periodically.

A correctly implemented grounding system significantly reduces power outages and the risk of electrical fires.

Protected Installation & Cabling

In greenhouses, cable lines are exposed to high humidity, temperature changes, and chemical effects. Therefore, the cables and installation used must be shielded and protected.

When cabling:

UV-resistant cables that are isolated against moisture and water should be preferred.

Cables should be laid in lines away from ventilation ducts and water pipes.

Cable conduits used outdoors should be steel or PVC coated.

Each system (lighting, irrigation, heating) should be connected to separate fuse groups to prevent overloading.

Protected installation prevents production stoppages by avoiding electrical faults.

Efficient Equipment Integration

Efficiently integrating electrical equipment operating within the greenhouse provides energy savings. Ventilation fans, LED lighting, heat pumps, automation systems, and motorized screens must work in harmony with each other.

In equipment integration:

High-efficiency LED lighting and low energy-consuming motors should be selected.

Heating and cooling systems should be paired with the automation panel, and energy optimization should be performed.

Irrigation systems and automation should be planned to balance the electrical load distribution.

This integration both lowers electricity costs and extends equipment life.

Monitoring & Maintenance

Regular monitoring and maintenance are mandatory for the greenhouse electrical system to operate without failure. The electrical panel, fuses, connection terminals, and sensors must be checked at certain intervals.

Monitoring and maintenance process:

Energy consumption should be tracked regularly to detect leakage or overloading.

The interiors of panels should be kept clean against dust, moisture, and oxidation.

Connections of sensor and automation systems should be tested to check data accuracy.

The electrical draw of fans, pumps, and motors should be measured to detect performance losses early.

Regular maintenance both increases safety and prevents unwanted interruptions in production.